The Invisikim skimmer lid system is not the first system of this type. There are other systems around, however, Invisiskim wanted to take this idea into the future.

Older systems incorporate stainless steel construction, however, as per Australian Standards AS NZS 3000-2007 Amdt 2-2012 Electrical installations, these steel systems require an electrician to connect an earth wire to them and run this earth wire back to the power point in which the pool filtration is connected. What if a system exists that does not require this additional work and significant costs?

A non-conductive system would solve this issue. There are other plastic systems out there that achieve this. But what if we could do it better!

The Invisiskim Skimmer Lid System incorporates advanced polymer plastics that are UV stabalised. The design adhears strickly to the safety requirements of AS1926.3-2010 Amnt 1

Examples of this include the ability to meet the total skimmer lid weight requirements of the lid part (including the paver or concrete) to weigh a min of 10.19kg. This is so small children cannot access the skimmer itself etc.

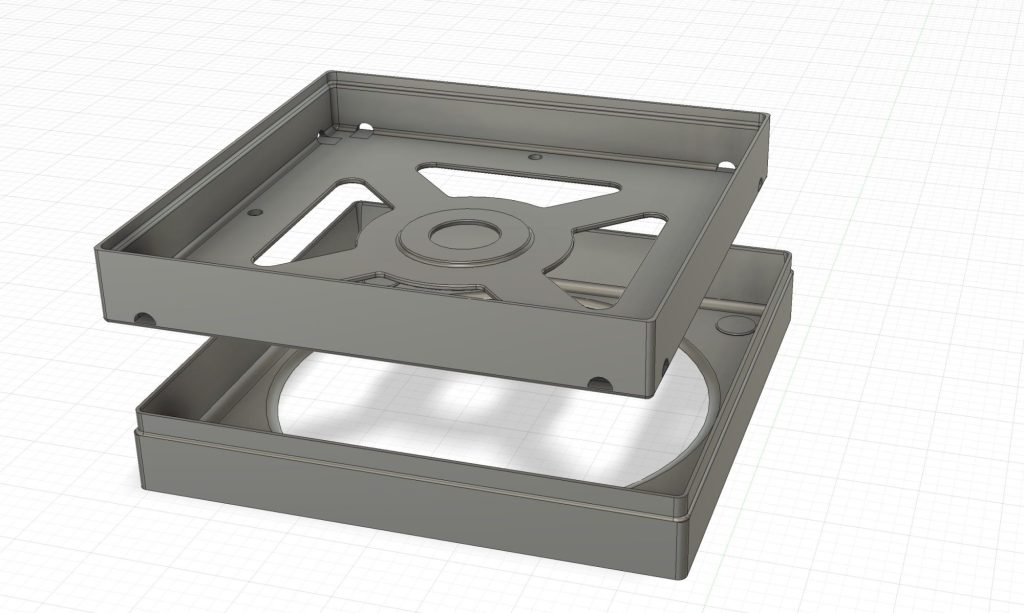

Another example is that AS1926.3-2010 Amt 1 required the lid to be vented AND that the vent in the lid has an opening a min of 315mm squared, which our system does.

Other amazing features include the lid being self-centering, unique levelling access holes for when installing the paver perfectly and a centre nut/vent that can still be centered perfectly, even if the install does not drill the required hole perfectly centre in the paver.